Bored Piles

Bored piles are cylindrical bodies made of concrete (with or without reinforcement) which are installed in the ground by a variety of methods. They transmit high structural loads into lower, load-bearing soils. When installed in rows or in secant configuration they can form a supporting wall for an excavation or steep slope, or cut-off groundwater. The length, diameter, material, geometry and layout of the piles can be varied according to their intended use.

Types of Construction Method

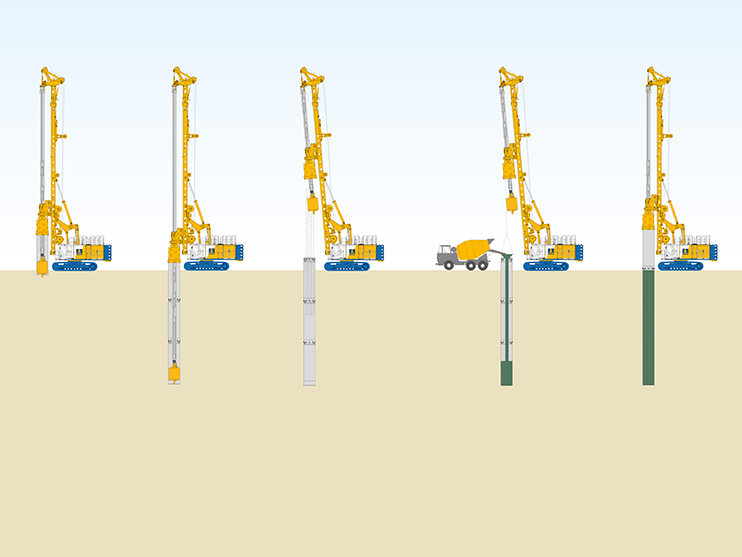

The rotary bored method is used to produce uncased, partially / fully cased or slurry-supported bored piles. The soil is excavated by a drilling tool mounted at the tip of a telescopic Kelly bar.

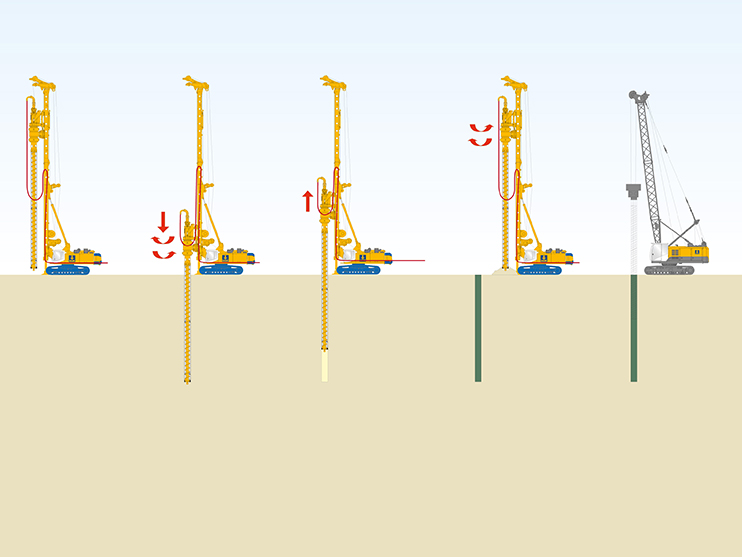

The CFA method is a rotary drilling technique which permits high drilling performance but to a limited diameter and depth. This method employs a continuous flight auger as the drilling tool. When the final depth is reached, concrete is pumped from bottom to top through the hollow stem auger. The reinforcement is installed subsequently, assisted by a cage vibrator where required.

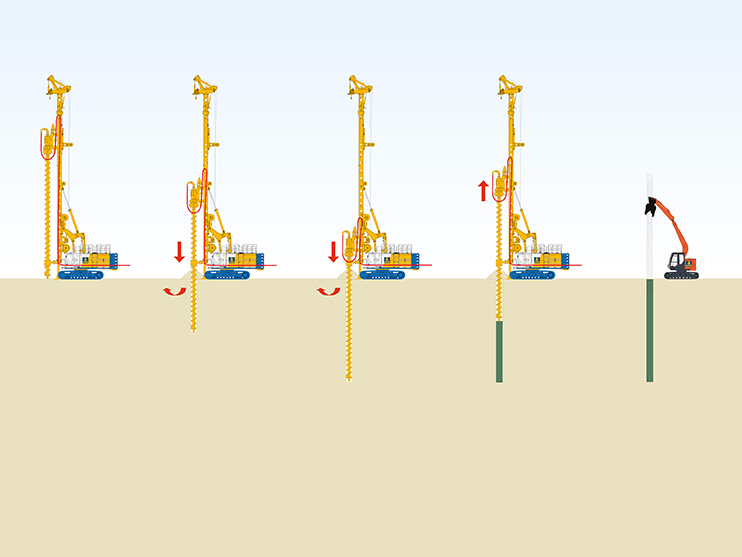

The cased CFA system links the CFA method with a full depth temporary casing. Where this method can be adopted, it is particularly advantageous due to its enhanced production rates compared to conventional rotary bored piling.

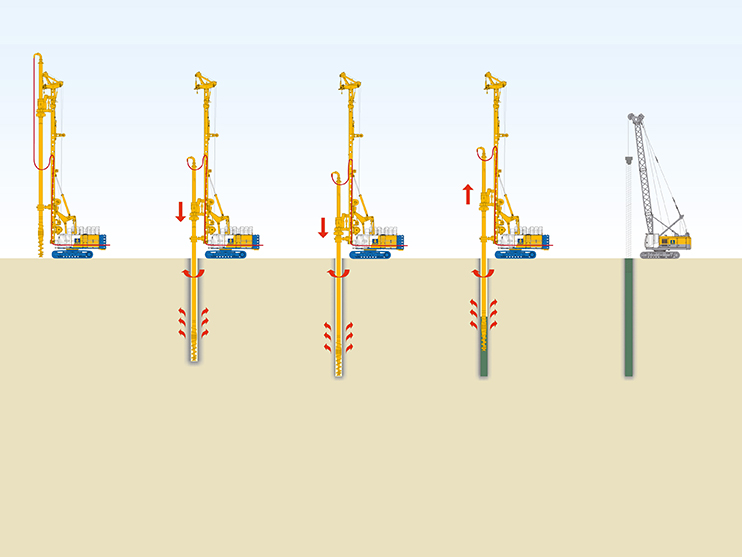

The FDP system has a key advantage over other techniques, in that it transports virtually no drilling spoil to the surface. It is primarily suited to displaceable soils (granular). During drilling and extraction, the surrounding soil is displaced, concreting and reinforcement is executed as in the case of the CFA pile.